Looking back (and ahead) at a "Day in the Life of a Process Engineer"

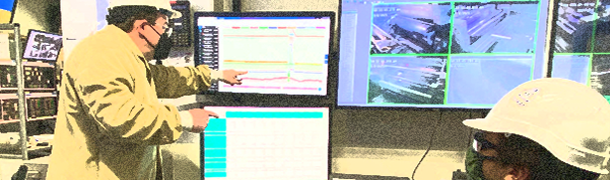

In his nearly 26 years of process engineering work at Toray Plastics, with almost 20 of those years in direct support of manufacturing, Mike Malone and his team have faced and overcome many challenges. So when we asked about his thoughts on what “a day in the life of a Process Engineer” was like, he had a chance to reflect on some of his main challenges, which boiled down to: communication, Process Control Management, and data analytics. Click to read the full article where Mike reflects on the evolving scope of his role in the most recent issue of Process Industry Informer.

Let's get digital, digital: Making sure your digital & analytics tools are pulling their weight

Remember that gym membership you got at the beginning of the year? It was so shiny and full of promise...Now 4 months in and the results aren't exactly what you were hoping for. Implementing new, digital technology can be a little bit like that (it's a stretch, but just go with me on this). They are both, after all, their own type of transformation. So how can make sure you get the best results from the digital and analytics tools - the metaphorical gym membership - that you've put in place? McKinsey dives in with a smarter way to digitize maintenance and reliability:

2 birds, 1 stone: How to improve your production and help your business function properly

When you realize there's a need to improve your production, it's important to sit back and analyze how you've been operating. Studies have shown that most organizations spend over 50% of major resources like labor and equipment process improvements alone. And it’s not that your staff isn't up to par, but that they face a challenge almost everyone can relate to: getting sucked into the day-to-day grind of troubleshooting and fighting fires. So how can you improve your production and help your organization run at optimum levels? Click to check out some suggestions:

Check out New Webinars on Demand